News

- Make the best use of "straw" and turn waste into treasure Gangbei District, Guigang City, Guangxi Province comprehensively promotes the comprehensive utilization of strawGangbei District, Guigang City, Guangxi Province actively uses straw comprehensive utilization technology to promote the use of straw as fertilizer, feed, and fuel, turning straw into treasure, realizing the organic unity of ecological protection and economic development, and helping to fight the "blue sky defense battle". In the sugarcane field of Wanghua Village, Gangcheng Street, Gangbei District, several straw balers were seen shuttling. Accompanied by bursts of roaring sounds, clusters of sugarcane leaves were "swallowed" into the machine, and after being rotated, compacted, and bundled, bundles of tightly bound straw bales were "spit" out from the tail of the machine and scattered on the field. The sugarcane fields have also become level and clean. It is reported that straw usually refers to the remaining part of rice, corn, sugar cane and other crops after harvesting seeds. The burning of straw will seriously damage the environment, cause air pollution and increase carbon emissions. In order to effectively improve the rural environment and protect the ecological environment, Gangbei District guides enterprises to use straw processing technologies such as straw fertilizer treatment, straw feed treatment, and straw energy treatment through the principle of "government guidance, enterprise leadership, market operation, and farmer participation". , carry out the comprehensive utilization of straw recycling, and turn the original "waste" straw into a valuable raw material for making feed and fertilizer, realizing a win-win situation of comprehensive utilization of straw, energy saving and environmental protection.

2023 03/07

- Buy sugarcane straw at 220 yuan per ton in Yinhai District, Beihai City, GuangxiThe baled sugarcane straw will be transported to the Yinhai District Straw Comprehensive Processing Center in Baojia Village, Pingyang Town, Yinhai District, Beihai City, Guangxi, and will not be burned again. Today, Yinhai District, Beihai City, Guangxi promotes the comprehensive utilization of straw recycling, which will completely change the traditional unscientific and unenvironmental protection of straw treatment, and achieve multiple harvests such as ecological and economic benefits. "Fucheng Town has a total of about 120,000 mu of sugarcane land, and we bundle and recycle about 1,300 mu of sugarcane straw every day." said Chen Kewei, mayor of Fucheng Town. According to reports, the Yinhai District Straw Comprehensive Treatment Center has built a comprehensive utilization production line with an annual processing capacity of 70,000 tons of straw, which will be put into operation in November 2022, basically meeting the annual processing needs of nearly 150,000 mu of sugarcane straw in the district. After a bundle of more than 200 kilograms of straw enters the straw pellet machine production line, it undergoes pressing, cutting and other processes to produce finger-sized pellet fuel for combustion in industrial enterprise boilers. In order to stimulate the enthusiasm of the masses to participate in the comprehensive utilization of straw recycling, the center purchases straw at a price of 220-250 yuan per ton, and establishes a "recycling-processing-utilization" upstream and downstream industrial chain to turn waste into treasure. At the same time, Yinhai District has also stepped up publicity work to the public to change the lack of awareness of the public's lack of understanding of the ban on straw burning; the component supervision team has implemented grid management, and solidly carried out centralized rectification actions for the ban on straw burning in the autumn and winter of 2022.

2023 03/07

- "Rotten firewood" is transformed into clean energy by biomass pellet machineA pile of waste wood, branches, and straws are turned into clean energy --- biomass pellet fuel through the biomass pellet machine production line, which provides heat for production enterprises and residents in the industrial park, forming biomass utilization and multi-energy complementarity. The raw material for this project is biomass, which mainly comes from fruit tree branches, sawdust, straw, etc. in the countryside. These biomass are used as green energy, which not only solves the problem of three piles in the surrounding countryside, turns waste into treasure, but also provides local villagers Increased income. At the same time, this project also drives the surrounding villagers to find employment at their doorstep, benefiting people with a radius of 50-80 kilometers. Before the implementation of this project, the straw and wheat grass in the surrounding farmers' homes were basically burned on kangs and pots. Almost every house in the village was piled up with branches and waste wood, which not only took up space, but also affected the appearance of the village. After the implementation of this project, everyone sold this "bad firewood" to the biomass pellet factory, which not only increased their income, but now when they go around the village, everything is clean. The completion of the biomass pellet machine project echoes the "double carbon" goal proposed by the country, realizes the complementarity and utilization of various energy sources, improves energy utilization efficiency, and optimizes the cleanliness, safety, and utilization of energy. The project is forming a demonstration effect at the same time , has effectively promoted the rapid development of the local economy.

2023 03/02

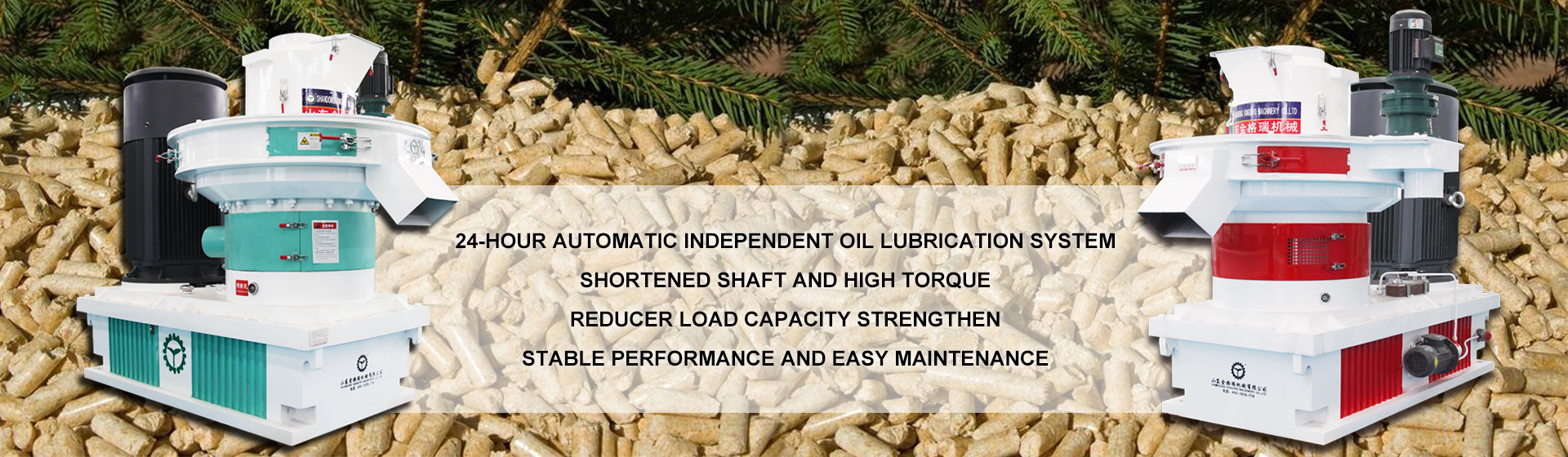

- A good helper for energy saving and emission reduction---Shandong Biomass GranulatorThere are many types of pellet machines according to the types of raw materials they process. Biomass pellet machines are one of the types of equipment specially used for processing biomass raw materials such as wood chips, straw, rice husk, and bark. These wastes can be solidified into high-density pellet fuel after processing, which has a very high utilization value and can directly replace coal as fuel. Biomass pellet machine equipment has also played a certain role in promoting energy conservation and emission reduction. Problems such as energy crisis and environmental pollution are particularly prominent in the new century. It is very important to optimize the energy structure to protect the environment and promote energy conservation and emission reduction. The following editor from Shandong pellet machine manufacturer will introduce the role of biomass pellet machines in energy conservation and emission reduction. . 1. Under the current environment of energy conservation and emission reduction, the market prospect of biomass energy is very promising. Biomass energy pellets can not only replace coal burning, but also improve the utilization rate of waste. Biomass pellet machine not only helps to protect the environment, but also realizes waste recycling, making wood chips, straw, rice husk, Peanut shells and other wastes have come into play. 2. Wood chips, wheat stalks, corn stalks, corncobs, peanut shells, rice husks, bamboo chips, bark, branches and other biomass materials are made into a cigarette-like shape with a very dense texture after being processed by a pellet machine. particles. The particles produced by the pellet machine do not produce sulfide during the combustion process. The combustion only produces carbon dioxide and water, which does not pollute the environment. Biomass resources are a renewable resource. The world generates dozens of times the energy needed by humans every year. . 3. With the increase of support policies in various places, practitioners in various places are constantly increasing, and at the same time, the number of pellet machine manufacturers is also increasing. Be cautious when purchasing pellet machines in the pellet machine industry, because most of the new pellet machine manufacturers are small pellet machine manufacturers, and there may be problems in pellet machine quality and after-sales service. We, Shandong Kingray, belong to one of the early batches of Shandong Zhangqiu biomass pellet machine manufacturers, and the quality is trustworthy. The above is about the role of the biomass pellet machine in promoting energy conservation and emission reduction. I hope it can help everyone.

2023 03/02

- Biomass pelletsOn February 13, the on-site promotion meeting of household biomass boilers and fuels in Shuangcheng District, Heilongjiang was held in Handian Town, actively guiding farmers to actively use clean energy and build beautiful villages. In an energy development company in Heilongjiang, everyone visited the demonstration of biomass civil stoves and the "coal" production line of biomass pellet machines, learned more about the use of boilers and thermal efficiency, and went to farmers' homes for on-site investigations to experience the power of biomass boilers scenes to be used. Heilongjiang has always taken the development and expansion of biomass fuel bases and striving to build China's "cow coal" township as its development vision, and is committed to the fuel production of cow dung. Replacing coal with "cow coal" not only reduces the environmental pollution of cow dung, but also reduces the burden of heating for farmers. At present, the production process of "ox coal" has been spread in many provinces in China. Participants fully understood the development prospects of biomass boilers and fuels through on-site demonstrations, accounting comparisons, technical explanations, and personal experiences. He also stated that it will be promoted to reduce cow dung pollution and promote rural environmental improvement to a new level.

2023 03/02

- How to save fuel pellets machined from biomass pellets?Biomass fuel particles have high purity and no other dirt that does not cause heat energy. Its carbon content is 75-85, its ash content is 3-6, and its moisture content is 1-3. There are no gangue bricks, stones, etc. that do not generate heat but consume heat The residue will control costs for the company. Biomass pellets are processed at room temperature by using the pressure wheel of the biomass pellet machine and the ring die to process the crushed biomass fuel straw, forestry and fruit industry waste and other raw materials in a hot state and high density. The relative density of raw materials is generally 0.1-0.13t/m3, and the relative density of particulate matter is 1.1.1.3t/m3, which is convenient for storage and transportation, and greatly improves the ignition characteristics of biomass fuel. As a new type of granular fuel, coal-fired boiler fuel has been widely recognized for its advantages; compared with traditional fuels, it not only has financial advantages but also has environmental protection and economic benefits, which meets the requirements of green development. How to save fuel pellets machined from biomass pellets? 1. To ensure the dryness of biomass particles, such raw materials are generally transported directly from the field to the production line at the same time, especially the raw materials of straw, before they are officially processed into pellet fuel, everyone should dry the straw. 2. Ensure waterproof work. There may be more rain and temperature in winter, especially after snowfall, when the snow melts, the temperature drops, and the environment becomes humid and cold, so the waterproof work must be done well. 3. Pay attention to the change of water content. The water content in the biomass pellets does not have to be too much. Cold and hot can easily cause qualitative changes, so we should store them in air-dry conditions.

2023 03/02

- Where can I buy environmentally friendly wood pellet fuel processed by biomass pellets? What issues should be paid attention to when purchasing?There are currently many manufacturers selling biomass pellet machines in the market, and there are also many manufacturers producing environmentally friendly wood pellet fuels, which are relatively easy to buy. Basically, there are several manufacturers in every province, city and county. However, when purchasing environmentally friendly wood pellets processed by biomass pellets, you need to pay attention to the following issues: (to avoid being fooled and being led by the nose by the manufacturer) First: Fully understand the boiler situation in your factory, how big is the boiler, how many tons, whether it uses steam, hot water or hot air, how high the temperature needs to be, how many kilograms the boiler pressure, etc., these information are easy to obtain If you don't understand, you can go to the boiler room and consult the boiler engineer. Second: The price of wood pellet fuel is different according to different wood chips (the following are listed for you, the price is from low to high) Building formwork granules: The cheap one is that building formwork granules are also pure wood, but they have high ash content and are easy to coke, so they are not suitable for small equipment. Miscellaneous wood pellet fuel: low calorific value of 3900 kcal, ash content of about 5, easy to coke, not suitable for small equipment. Pine wood pellet fuel: low calorific value of about 4200, ash content of about 1, low ash content, high calorific value, basically suitable for all boilers on the market. Pinus sylvestris pellet fuel: low calorific value is about 4200-4300, ash content is less than 1, the preferred fuel for equipment that is afraid of coking. The ash content directly affects the calorific value of environmentally friendly wood pellet fuel. If the ash content is high, the calorific value will be low. You are using biomass burners, biomass generators and other small equipment that are prone to coking. It is recommended to use wood pellets with low ash content such as pine pellets and sylvestris pine pellets. On the contrary, you can use cheap fuels. Be careful not to use peanuts. Hulls, straw products pass off as wood pellet fuel.

2023 02/28

- Analysis of the causes of cracks in the pellets produced by the biomass pellet machineIn the production of biomass pellet machine, sometimes there will be particles with abnormal appearance. Experienced pellet machine manufacturers will know the cause of this situation and can quickly eliminate it. For inexperienced or new wood pellet manufacturers For example, sometimes you can't find the crux of the problem, and you can only ask for help from the outside world or the pellet machine manufacturer. The following is the introduction of the causes and improvement methods of 7 common wood pellets with abnormal appearance. This is a summary of Shandong Jingerui pellet machine manufacturer's years of work experience in pellet machine development and debugging, for comparison in the production of wood pellets refer to. 1. The sawdust pellets are bent and have many cracks on one side This phenomenon usually occurs when wood pellets leave the ring die. In production, when the position of the cutter is adjusted farther from the surface of the ring die and the edge of the knife is blunt, the particles are easily broken by the cutter instead of being cut off when extruding from the die hole. At this time, some particles bend to one side and the other There are many cracks on one side. The wood pellets tend to break from these cracks when entering the cooler for cooling or transportation, resulting in too much powder or too short pellets produced. Improvement method: Increase the compression force of the ring die on the wood pellets, that is, increase the compression ratio of the ring die, thereby increasing the density and hardness of the pellets; Grind the sawdust raw material wood chips finer to increase the compactness of the wood chips and prevent the wood chips from being soft; Adjust the distance between the cutting knife and the surface of the ring die, usually the distance between the knife edge and the outer surface of the ring die is not greater than the diameter of the wood pellets produced, or use a sharper cutting blade; 2. Horizontal cracks across the entire wood particle Somewhat similar to the phenomenon in case 1, the cracks occur in the cross-section of the wood particle, but the particle is not bent. This can happen when pelletizing fluffy wood chips that contain more fibres. This kind of wood pellets is often produced when the wood chips are squeezed into the granulation hole of the ring die, because it contains fibers longer than the hole diameter. , producing a fir bark-like wood pellet appearance. The improvement method is to increase the compression force of the ring die on the wood chips, that is, to increase the compression ratio of the ring die; to control the crushing fineness of the fibers, and the maximum length cannot exceed one-third of the particle diameter; to reduce the output to reduce the passage of wood chips The speed of the die hole increases the compactness; 3. Biomass pellet machine produces vertical cracks During the production process, due to the type of dryer selected by some customers, the raw materials cannot be dried evenly, resulting in uneven moisture content of the raw materials. The elasticity and bounce off, resulting in vertical cracks. The way to improve is to improve the drying effect of the dryer and increase the effective length of the die hole. 4. Sawdust particles produce radiation cracks from one source point The main reason for this situation is that the sawdust contains relatively large sawdust. Raw materials with similar fiber levels will be extruded and fused with each other when they are granulated. If there are larger fibers, the interaction between fibers will be affected. He is not as easy to soften as other finer raw materials, but when cooling, due to the different degrees of softening, the shrinkage is different, resulting in radial cracks. The improvement method is to properly control the thickness and uniformity of the powdered feed raw materials, and add a simple sieve to sieve the sawdust with larger particles before pelleting. 5. The surface of the pellets is uneven This situation is that the powder used for granulation contains large particle raw materials that have not been crushed or semi-crushed. Because the particles are relatively hard and relatively large, they cannot be well combined with other raw materials when passing through the die hole of the granulator. Together, the grains appear bumpy. The way to improve is to properly control the thickness of powdery raw materials. 6. The color of individual particles or particles is inconsistent, commonly known as "flower material" The main manifestation is that the color of individual particles extruded from the ring die is darker or lighter than other normal particles, or the surface color of individual particles is inconsistent. The reasons for this phenomenon mainly include the following aspects: There is recycled material for repeated granulation in the silo to be granulated. The granulated pellets can only become finished materials after cooling and screening. The fine powder or small pellets after screening often enter the process for re-granulation, usually into the mixer or the granulation bin. Because this kind of recycled material is re-granulated, when it is unevenly mixed with other raw materials or mixed with recycled small particles, sometimes "flowery material" will be produced. 7. The smoothness of the inner wall of the ring die aperture is inconsistent. Due to the inconsistency of the finish of the die hole, the resistance and extrusion force of the particles during extrusion are not the same, and the color change is not consistent. In addition, some ring dies have burrs on the small hole walls, and the particles will scratch the surface during extrusion, resulting in different surface colors of individual particles. For the above-listed reasons for the occurrence of "flowers", the improvement method is very clear, control the recycled materials, and for the particles that are prone to "flowers", the recycled materials should be mixed with the raw materials and then crushed again; The ring die with guaranteed quality is used to control the smoothness of the die hole. If necessary, the die hole is sanded before use. In short, for the particles with abnormal appearance in the production of wood pellet machine, several representative manifestations are discussed above, and some abnormal appearance of particles are not listed here because they are not representative. It can be seen from the above discussion that there are many reasons for these phenomena, and they are not completely isolated from each other. This requires us to do more analysis and grasp the key points of the problem when dealing with such problems in actual work. Only then can the problem be solved. Hope this article can help you all.

2023 02/28

- Do you know the switching sequence of the biomass pellet machine?Preparations before starting the biomass pellet machine 1. Check whether the gearbox internal machine (gear) oil is sufficient; 2. Whether there is lubricating oil in each lubricating bearing part; 3. There is organic oil in the oil cup; 4. Whether there are wood blocks, stones and other sundries in the granulation room; 5. Whether there are iron blocks, iron wires, etc. on the magnet 6. Whether the wires in the control cabinet are broken, damaged, discolored, whether the electrical components and terminals are loose, and whether the voltage is normal. Boot sequence: 1. Start the main motor, wait for the step-down to start normally, start the forced feeding, open the front oil inlet plate, start the speed-adjusting hinge after 2-4 minutes of oiling, and adjust the frequency of the speed-regulating hinge to 6HZ, see The operation of the biomass pellet machine, if it is running normally, wait another 2 minutes and adjust to 8HZ to see the operation of the biomass pellet machine, and gradually increase it. The current value of the main engine (200A-240A) cannot be lower than 180A, nor higher than 240A ; 2. The operator cannot leave the electric control cabinet at will in order to adjust the current at any time. When the moisture content of the raw material is high, the electrorheological pointer will go down. At this time, the current pointer should be adjusted upward. When the moisture content of the raw material is low, the current The variable pointer will go up, at this time, the current should be adjusted downward, and the current should always be controlled below the rated current; Shutdown sequence: 1. When shutting down, first stop the agitator in the raw material bin, then stop the speed-regulating auger, then open the feeding plate to add oil, let the main machine idle for 3-5 minutes, then turn off the forced feeder, and then turn off the main machine. The operation sequence is; the motor that is turned on first is turned off later, and the motor that is turned on later is turned off first. 2. Start-up sequence: main machine - forced feeding - speed-adjusting reamer - raw material bin agitator; 3. Shutdown sequence: raw material bin agitator - speed-adjusting reamer - forced feeding - main engine.

2023 02/28

- New Biomass Fuel Environmental Protection Boiler in Sanhe Huizu Township: Let the masses live a "green and warm winter"In 2022, Sanhe Huizu Township will actively explore a new model of heating straw through biomass boilers, purchase and install two new biomass fuel environmental protection boilers and supporting equipment for the Suqin area, and upgrade the supporting boiler room. The use of straw instead of coal-fired raw materials for central heating greatly reduces resource consumption and heating costs compared with the old-fashioned boilers in the past. At the same time, it can effectively solve the problem of environmental pollution caused by burning straw. In order to do a good job of heating, which is a matter of people's livelihood, Sanhe Hui Township first tried it first, attached great importance to the construction of the boiler project, rushed to the construction period, and ensured the quality. The material environmental protection boiler was put into use. At present, the central heating coverage of environmentally friendly boilers covers Suqin residential areas, border police stations, agricultural reclamation groups, schools, etc., benefiting more than 600 households with more than 3,800 people. After replacing the new boilers, the overall heating efficiency in the Suqin area has been significantly improved, and the indoor temperature has risen significantly, reaching above 22°C, making residents' homes feel warm. But how the heating effect is, the feelings of the masses are the most convincing. "Now the radiators in the house are hot, and the whole house is much warmer than before." Ms. Sun, a resident of Suqin, said excitedly. The new central heating method not only heats the house and warms the hearts of the people, but also finds a good way out for the disposal of straw in the Suqin area, truly achieving recycling and environmental protection. For people's livelihood projects, the key lies in actions and results. The new biomass fuel environmental protection boiler project in Sanhe Hui Township has not only warmed the lives of the people, but also beautified the regional environment, making Suqin's winter a green winter, a winter that benefits the people, and a heart-warming winter.

2023 02/28

- Ningxia: Promote the resource utilization of biomass energy and accelerate the promotion of biomass instead of loose coal for heatingRecently, the Ningxia Autonomous Region Housing and Urban-Rural Development Department issued the "Ningxia Hui Autonomous Region Urban and Rural Construction Field Carbon Peak Implementation Plan", which mentioned: Promote the construction of solar photovoltaic integration in new buildings. By 2025, the proportion of new industrial plants and public buildings with photovoltaic integration will reach 50%. Promote the installation of solar photovoltaic systems on the roofs of existing buildings. By 2025, the proportion of solar photovoltaic systems in existing public buildings such as party and government agencies, schools, and hospitals will reach 15%. Actively promote the application of solar thermal buildings. Promote the application of geothermal energy and biomass energy according to local conditions, promote the multi-energy complementary technology of solar energy and air source, and promote clean heating. Promote the resource utilization of biomass energy, and give priority to the use of solar energy, air source thermal energy, shallow geothermal energy, etc. to meet the energy needs of agriculture and rural areas. Support the national county-wide pilot counties (districts) for rooftop photovoltaic development, combine the investigation and rectification of hidden safety hazards in rural houses, seismic reinforcement, heat preservation and energy conservation, promote sunshine residential projects, and promote the installation of solar photovoltaic systems on farmhouse roofs, courtyard open spaces, and agricultural facilities. Vigorously promote clean heating, and promote solar energy + air source heat pumps (water source heat pumps, biomass boilers) and other small renewable energy sources for heating in rural areas that are not covered by central heating. Accelerate the promotion of biomass briquette fuel + biomass boilers to replace loose coal for heating. Encourage biomass cogeneration, household waste power generation, wind power and photovoltaic power generation for heating. Actively develop geothermal energy heating, and develop and utilize shallow, medium and deep geothermal energy according to local conditions. Continue to increase the transformation and upgrading of rural power grids, promote the further improvement of rural electrification levels, and encourage the use of high-efficiency and energy-saving household appliances, semiconductor lighting products, and energy-saving and environmentally friendly stoves.

2023 02/28

- Tianjin Beichen District: Vigorously promote the comprehensive utilization of biomass fuels in an orderly mannerRecently, the Beichen District People's Government of Tianjin issued the "Tianjin Beichen District Carbon Dafeng Implementation Plan", which mentioned: Promote the carbon peak of the building materials industry. Promote fuel substitution, vigorously promote biomass fuels and waste-derived fuels, and reduce fossil energy consumption. Vigorously develop new energy sources. Promote the comprehensive utilization of biomass energy in an orderly manner to ensure the stable operation of Everbright and Morningside Lectra waste incineration power generation projects. Promote rural construction and low-carbon transformation of energy use. Accelerate the application of renewable energy such as biomass energy and solar energy in agricultural production and rural life.

2023 02/28

- Teach you how to distinguish the fuel pellets of the biomass pellet machineAt present, the pellet industry and the biomass pellet machine industry are extremely prosperous. Among them, many unscrupulous merchants take advantage of troubled waters in order to shoddy goods and harm the interests of customers. When customers choose biomass pellet machine and pellet fuel, they only consider the price, but ignore the quality of the product itself. In response to many problems, the editor of the pellet machine manufacturer will provide you with several methods to identify the pellets, and I hope it will be helpful to you. The raw materials of biomass pellets are various, including wood chips, straw, peanut shells, cotton stalks, domestic waste, straw, corn stalks, etc. Among them, the fuel value of wood chips is fuel, followed by straw and domestic waste. 1. Observe the color, luster, purity, burnt ash and various raw materials of the particles. Sawdust pellets and straw pellets are mostly light yellow or brown, and domestic waste pellets are black; purity refers to the state of granulation, the better the granulation conditions, the longer the length, the less debris, the better the pellets; the pellet fuel produced is burned The lower the final ash content, it means that the raw material is pure and of good quality. Pure wood pellets have an ash content of only 1%. At least, the ash content of straw particles is slightly larger than that of domestic waste particles, which can reach 30% by mass. In addition, many factories add impurities such as lime and talc to the pellets to save costs. After burning, the ash is white; the better the particle quality, the higher the gloss, and the live waste particles are dull. 2. Smell the smell of the particles. Since biomass pellets cannot add task additives during the production process, most of the pellets still maintain the smell of their raw materials. Sawdust granules have the smell of wood, various straw granules also have its unique straw smell, and domestic waste granules have the smell of fermentation in the ditch. 3. Touch the pellets by hand to identify the quality of the pellets. If you touch the particles with your hands, the surface is smooth, no cracks, no debris, and the hardness is high, indicating good quality; if the surface is not smooth, there are obvious cracks and many debris, the quality of the particles that can be crushed by hand is not good.

2023 02/28

- Danjiangkou City Ecological Energy Center, Hubei Province: Stoves are provided in the cold winter to share the "beautiful environment and warm winter"1: Hey everyone! As we were discussing how to survive the winter, wow, look at what you have in your hands, what is it? 2: Oh, this is a newly issued biomass stove in the village. It can use biomass fuel processed by biomass pellets, like firewood, for cooking and heating, and can also reduce our coal consumption. 1: I see, what a great idea! 3: That's right! No longer have to worry about yelling "too cold" lines in winter! 1: Now that there is this stove, besides making us comfortable and saving money, are there any other benefits? 2: There are more! This stove is safer than traditional stoves, it does not produce smoke, and it does not smudge eyes. 4: I really want to have one! Fang Shaoqi, a scattered five-guarantee household in Yangxigou Village, Sanguandian Street Office, Danjiangkou City, said excitedly while looking at the stove. Danjiangkou City Ecological Energy Center, as the supporting unit of the village, distributed more than 270 biomass stoves to the village. According to the "Biomass Stove Issuance Plan" formulated by the village committee, the first batch of farmers who enjoy the distribution include: more than 180 households in needy groups, scattered five-guarantee households, and families with disability certificates (first and second grade). Based on the needs of the masses, the center implements the concept of "co-creation of a beautiful environment and a happy life", gives full play to the functions and advantages of the unit, and solves the problems of winter heating, living environment and firewood felling for farmers in suburban villages. "Beautiful environment and warm winter" shared goal.

2023 02/28

- Biomass pellet machine is conducive to the development of clean energyThere are biomass fuel processing plants in every province, from small family workshops to mass production, and the situation of biomass pellet plants is improving year by year. Because the renewable green energy processed by biomass pellets has investment potential in biomass fuel. With the accelerated development of the biomass pellet machine equipment machinery industry, more and more users have begun to invest in pellet machine production lines. Users see that the device has a lot of room to grow. Why do you say that? This is because the biomass pellet machine mainly recycles, processes and utilizes a large number of insignificant wastes such as household waste leftovers, crop straws, rice husks, and fruit shells, which reduces the pollution of waste to the environment and effectively regenerates green resources. Rate. my country has a vast territory and abundant resources. Keep pace with the times, develop and manufacture biomass fuel industry, benefit the country and the people, and the products will not be surplus. The first-grade biomass fuel is exported, the second-grade biomass fuel is sold domestically, and the biomass fuel powder below the third grade can be further processed without useless waste. As long as the price of raw materials is not particularly high, running a pellet plant is fine. Customers can choose biomass pellet machine equipment according to local raw materials. From the perspective of market sales in 2023, large-scale biomass fuel manufacturing equipment such as fully automatic biomass pellet machine production lines will be more popular. We hope that customers can seize the opportunity. I am waiting for you at the Shandong Jingrui pellet machine manufacturer. If you want to buy pellet machine equipment in 2023, you will come to Shandong pellet machine factory to have a look.

2023 02/28

- The difference between different raw materials to make biomass pelletsThe more common biomass pellets in the current market can be roughly divided into three types: crop waste, mainly produced in rural production such as straw, fruit husk, rice husk, etc.; secondly, forestry production waste, Sawdust and shavings from furniture production, waste wood, branches, and bark from logging; the third is relatively rare, animal manure, waste clothes, and domestic garbage. And which kind of biomass particles under these different materials is better, and which one is more economical, next, the editor of Shandong Jingerui Machinery will analyze it for you. First of all, we can judge by the moisture content in the biomass pellet fuel. The biomass pellets produced are too dry and the moisture is too high. The combustion efficiency of the pellets kept at an appropriate moisture value is higher. Particles with too much moisture are easy to deteriorate, and they are easy to not burn in the boiler when they become black and damp. Wood pellet fuel is a relatively high-quality biomass fuel with high density and compactness. At the same time, the calorific value of combustion is high, and the ash content can reach about 1%. The particles made of straw raw materials have a slightly larger ash content, and the particles made of domestic waste have a higher ash content. At the same time, the cost performance of the fuel is also very important. The heat of the particles produced by the fuel type is also very different, and the calorific value of the fuel is one of the key elements of the biomass pellets, and the calorific value of the pellet fuel is relatively large. Peanut shell, wood and other pellet fuels.

2023 02/28

- Characteristics of biomass pellet machined fuel compared with coalThe combustion characteristics of the fuel processed by biomass pellets are very similar to those of medium-quality coal, and compared with medium-quality coal, they have the following characteristics: ①The calorific value and ash content of biomass pellet fuel are about 10% lower than the calorific value of medium coal. However, biomass pellet fuel burns energy under working conditions, but coal cannot burn, and 10% to 15% of the slag remains combustible. Therefore, the calorific value of the two is very high in actual use. ② The ignition gas of biomass pellet fuel is better than that of coal, which is convenient for ignition and greatly shortens the start-up time of firepower. ③ The solid consumption of biomass pellet fuel is less than that of coal, which reduces the cost of discharging coal ash and environmental pollution. The solid discharge of biomass pellet fuel is all ash, accounting for about 0.4%~7.0% of the total weight; while the solid discharge of coal combustion The discharge is a mixture of ash, alkali and residual coal, about 25% to 40% of the total weight. ④ Coal is much more harmful to the environment and corrodes boilers than biomass pellet fuel. Soot contains a large amount of granular C and toxic SO2, CO and other corrosive gases. The main component of biomass pellet fuel is C-H organic matter, and there is no granular C and SO2 in the smoke, mainly C-H evaporated gas, and its SO2 and CO consumption are close to zero; the smoke color is lower than Ringelmann level 1 during combustion, and will It has greatly reduced environmental pollution and carbon dioxide emissions, and biomass pellet fuel has the reputation of "clean fuel" in my country. ⑤ The cost and time of using biomass pellet fuel for boiler fuel is less than that of coal. A 0.5t boiler burning biomass pellet fuel costs 11% less than coal, and saves time by 34%. A 0.5t boiler uses 10% less fuel than coal, saving 16% time. ⑥The continuous burning time of general biomass pellet fuel is 8~10 times higher than that of soft bulk materials, and it is in a stable and continuous burning state.

2023 02/28

- Fuel pellets machined from biomass pellets are relatively reliable and environmentally friendlyFuel pellets machined from biomass pellets are a class of environmentally friendly clean fuels. It can be directly formed by crushing, crushing, granulating, drying and other links. Relatively speaking, many choices of fuel particles can be said to be relatively reliable and environmentally friendly. Combustion particles are sent into the furnace by the screw feeder, and under the action of high-temperature smoke and dust and a return air, they are slowly conveyed by the screw, dried, ignited and burned. In this link, a large number of volatile molecules are deposited and burned obviously, producing The high-temperature smoke generated by the material fuel passes through the pellet burner to wash the main heating surface of the boiler, enters the economizer and air preheater on the heating surface of the boiler, then enters the dust collector, and then is discharged into the air through the chimney. The non-alkaliized fuel moves to the back of the grate until it burns out, leaving a little ash. l Enter the slag outlet behind the grate. An important combustion characteristic of boilers fueled with pellets is the graded air distribution. Environmentally friendly combustion pellets realize regional combustion, which not only ensures the environmental protection and efficiency of the boiler, but also greatly improves the utilization rate of pellet fuel. The emergence of pellet fuel can meet the requirements of different industries, which is not only environmentally friendly, but also economical. my country allows fuel pellets to be used as living fuelwood in rural areas, and straw burning in fields is strictly prohibited. Biomass molding fuel is a kind of molding fuel such as small pieces and pellets, which can be directly burned by using straw-like agricultural solid waste as raw material through crushers, pulverizers, biomass pellet machines, dryers and other processing equipment. New clean fuel. The complete set of equipment for biomass molding fuel molding processing includes feeding system, molding system, discharging system, and power distribution system. The main production equipment from raw materials to products includes loading and cutting machines, crushers, conveyor belts, biomass pellet machines, pelletizers, dryers, packaging machines, etc.

2023 02/28

- The biomass pellet fuel project in Gengma County, Lincang City, Yunnan Province supports green and low-carbon developmentA few days ago, when I walked into the biomass pellet fuel processing plant in Gengma County, Lincang City, Yunnan Province, piles of raw materials such as sugarcane tips, waste wood chips, crop straw, and wood scraps were waiting to enter the workshop for processing. into biomass pellet fuel. The person in charge of the pellet company introduced: "Biomass pellet fuel uses sugarcane leaves as the main raw material. The company's annual production capacity is 50,000 tons, which can cover 152,000 mu of sugarcane leaf no-burning areas." Biomass pellet fuel is a new type of clean energy that can be burned directly. Its advantage is to fully utilize biomass energy to replace coal. It is a major problem of air pollution caused by local incineration, which is in line with the concept of environmental protection and circular economy, and is of great significance to saving resources, protecting the ecological environment, and promoting the development of enterprises and regional economies. The county's 2022 investment promotion project will introduce a biomass pellet fuel project. Through Gengma Town, it will cooperate with the government and enterprises of enterprises. Gengma Town will purchase equipment and lease it to enterprises, and the enterprises will transform the standard factory buildings in the park for production and operation. The total planned investment is 100 million yuan. Construction in three phases. The first phase of the project will start in September 2022, complete equipment installation and commissioning at the end of November, and be officially put into operation in January 2023. After the first phase of the project is put into operation, it can realize an annual output of 50,000 tons of biomass pellet fuel, with an annual output value of 40 million yuan. After the project is fully put into production, it can realize an annual output of 200,000 tons of biomass pellet fuel, with an annual output value of 160 million yuan. At present, the production of the first phase can be sold out in the county, and the second and third phases can be sold outside the city and outside the province after they are put into production. The biomass pellet fuel project in Gengma County, Lincang City, Yunnan Province supports green and low-carbon development.

2023 02/28

- Fuel pellets machined from biomass pellets are relatively reliable and environmentally friendlyFuel pellets machined from biomass pellets are a class of environmentally friendly clean fuels. It can be directly formed by crushing, crushing, granulating, drying and other links. Relatively speaking, many choices of fuel particles can be said to be relatively reliable and environmentally friendly. Combustion particles are sent into the furnace by the screw feeder, and under the action of high-temperature smoke and dust and a return air, they are slowly conveyed by the screw, dried, ignited and burned. In this link, a large number of volatile molecules are deposited and burned obviously, producing The high-temperature smoke generated by the material fuel passes through the pellet burner to wash the main heating surface of the boiler, enters the economizer and air preheater on the heating surface of the boiler, then enters the dust collector, and then is discharged into the air through the chimney. The non-alkaliized fuel moves to the back of the grate until it burns out, leaving a little ash. l Enter the slag outlet behind the grate. An important combustion characteristic of boilers fueled with pellets is the graded air distribution. Environmentally friendly combustion pellets realize regional combustion, which not only ensures the environmental protection and efficiency of the boiler, but also greatly improves the utilization rate of pellet fuel. The emergence of pellet fuel can meet the requirements of different industries, which is not only environmentally friendly, but also economical. my country allows fuel pellets to be used as living fuelwood in rural areas, and straw burning in fields is strictly prohibited. Biomass molding fuel is a kind of molding fuel such as small pieces, pellets, etc., which can be directly burned by using straw-like agricultural solid waste as raw material through crushers, pulverizers, biomass pellet machines, dryers and other processing equipment. New clean fuel. The complete set of equipment for biomass molding fuel molding processing includes feeding system, molding system, discharging system, and power distribution system. The main production equipment from raw materials to products includes loading and cutting machines, crushers, conveyor belts, biomass pellet machines, pelletizers, dryers, packaging machines, etc.

2023 02/25

Email to this supplier